Best Value: Long Link Mill Chain or Engineered Chain?

There are two main types of industrial chain: round link chain and engineered chain. While engineered chain for power transmission […]

Read MoreJuly 17, 2024 | Articles

Changing out a sprocket can be time consuming and expensive.

Production needs to be stopped, machinery locked out, and maintenance operators need to be called in. Depending on your setup and mounting options, machinery may need to be taken apart to access the sprocket on the shaft.

If the sprocket is big enough, several people may be required to move and install the sprocket due to the size and weight of the steel. Sometimes lifting devices need to be used to safely accomplish this process, adding new complexities into the mix.

It’s for these reasons that split sprockets have been gaining traction in industrial applications.

Contents:

Most split sprockets come with mounting hardware, usually bolts. Some manufacturers suggest that if you make the bolts big enough, that’s all you need to run your sprockets at their full potential. Let’s explore that idea a bit…

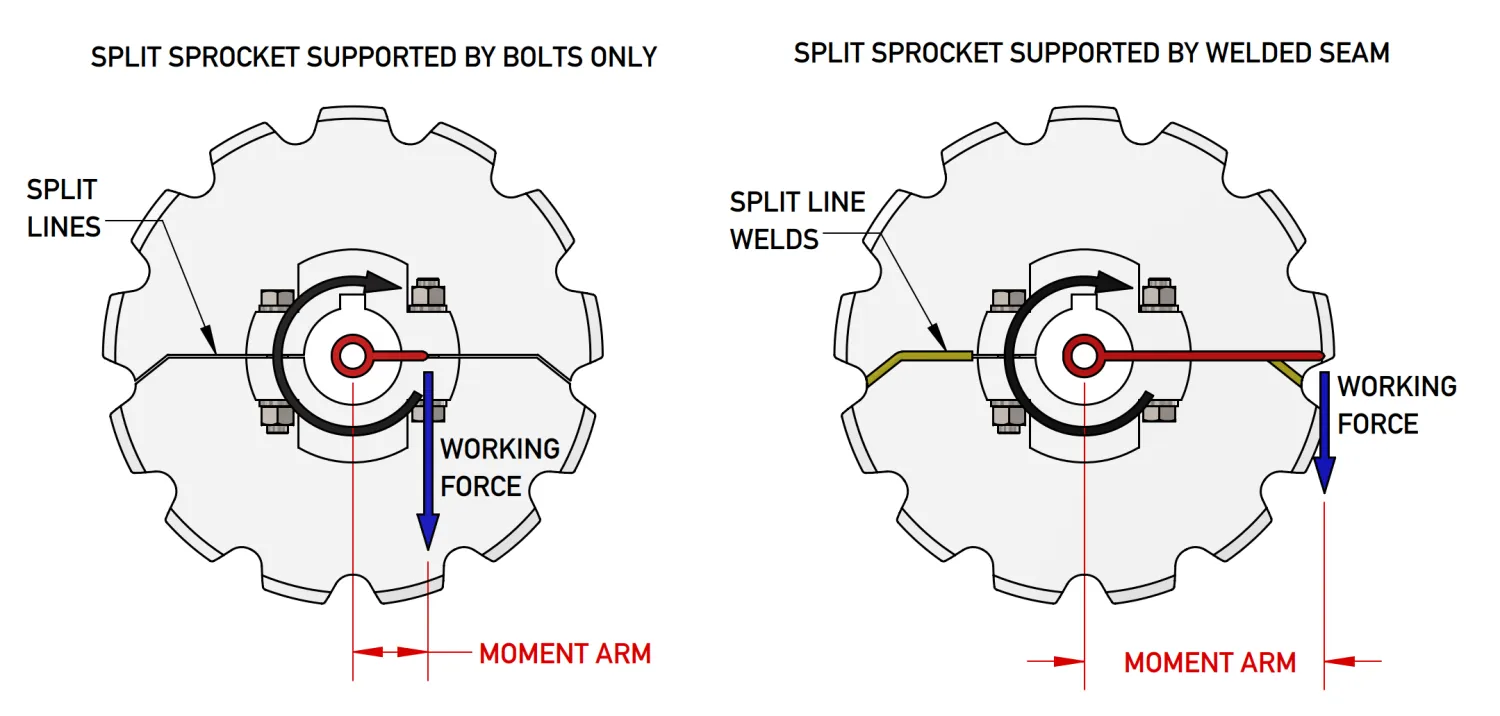

Hubs on split sprockets can take the load of the full sprocket, but that’s not their intended purpose. If possible, split sprockets should be welded or supplemented with reinforcement plates along the seam.

This transfers the moment arm from the inside of the sprocket (the hub) to the outside (the teeth), increasing the amount of torque the sprocket can use to drive the chain (or vice versa). Torque is calculated by multiplying the force exerted around an axis by the length of the moment arm. (T= F x MA)

By lengthening the moment arm from the hub of the sprocket to the teeth, we effectively increase the force applied to the chain.

It is always best practice to avoid relying on a mechanical fastener in an application involving tension and strain, not to mention heavy vibration. Each half of the sprocket exerts force on the bolt in a different direction as it moves. Bolts offer excellent performance at keeping two items together (their “normal force”), but are far weaker when experiencing shear force (force applied perpendicular to the axis of the bolt). Pulling a bolt apart is extraordinarily difficult, but breaking it by applying shear force is relatively simple. This principle is exactly how bolt cutters work: opposing forces are applied perpendicular to the bolt until it breaks.

Vibration of the sprocket is increased when it is cut in half, as each piece is able to vibrate independently. This vibration can cause the bolts to experience additional shear force, resulting in component failure, or simply cause the bolts to come loose.

This is why it’s best practice to weld (stitch) up the seam of a split sprocket: you solve not only the moment arm problem, but also the vibration issue.

There are also split sprockets on the market that don’t come with any mounting hardware. These sprockets are able to function at full capacity once installed, but necessitate a full weld to operate. Weld-only split sprockets are uncommon due to the difficulty of installation compared to bolt-on hubs. We only mention it here to illustrate that the weld on a split sprocket is sufficient to allow for full operation, and should be considered a primary load-bearing solution, to be used in conjunction with hardware.

Even though we don’t recommend relying on mounting bolts as the sole fastening method, bolts have another key benefit: they allow for preload (torque) on the hub before the sprocket is welded along the split line, taking the load off the hardware but also ensuring that the correct tension and preload is achieved on the hub for optimal sprocket life.

If you’re considering split sprockets for an idler application (non-keyed) see our article on the benefits and characteristics of idler sprockets. If you’re considering split sprockets for keyed drive applications, you should check out our article on the different types of drive sprockets.

Welding a split sprocket is not always viable in the workplace. For example, equipment and environmental considerations may place restrictions upon welding in a work environment (i.e. no hot working permit). In this case mechanical fasteners (bolts) are relied upon for the strength of the sprocket. This approach is sufficient for some applications, but restrictions aside, provides no mechanical advantages.

If welding the seam of a split sprocket is not a viable option in your application, reinforcement tabs may be used. Reinforcement tabs allow a bolt to pass through the sprocket, providing another anchor point besides the hub to resist twisting and separation, while still being easily removable.

Some companies weld all split sprockets as a matter of policy, so you may encounter situations where both reinforcement tabs and welding are used simultaneously. This is also occasionally used in applications where the sprocket is serving an especially critical role, although solid sprockets generally serve this purpose best.

There’s no such thing as a standard sprocket configuration. Some equipment is simple, and others have one or more sprockets deep within the equipment. These setups will require that the equipment be partially disassembled to provide access to the mounting assembly.

Space may also be a factor limiting accessibility. If your complete assembly is inaccessible, but you can easily access the sprocket itself, this may be a good case for a split sprocket.

Incorporating split sprockets eliminates these frustrations and greatly reduces changeout time by allowing access to the mounting bolts for easy installation and removal.

Small sprockets are only a few ounces in weight, but the largest solid sprockets weigh hundreds of pounds and require use of machinery to lift them in position.

While the final weight of the sprocket will be the same that of a solid sprocket, split sprockets are made in several different pieces, each a manageable size to be installed by hand.

Often drive sprockets are situated behind the scenes: under conveyor channels or catwalks, or close to walls. This makes installation difficult.

Sprockets can range from tiny 1” units all the way up to massive sprockets 20+ feet in diameter.

Installing a sprocket of this size can be an awkward endeavor, especially when space is at a premium. Split sprockets allow for easy installation from a wider range of angles, making them a great fit for tight environments.

Split sprockets have a higher sticker price than their solid cousins due to the increased manufacturing work required to create a design that incorporates additional hardware and components while still being able to handle a serious workload.

The savings here come from the labor savings when compared with installing a solid sprocket.

Large sprockets often require a crew of 2-3 members to hold the sprocket while it’s attached, and to disassemble and reassemble the drive assembly in order to access the mountings. This process can take several hours, depending on the complexity of the machine.

If a lifting device is required to lift and hold the sprocket during the process, additional costs will accrue with the extra man-hours required to transport and position the device, as well as the high initial cost of utilizing the equipment.

Split sprockets can accomplish the same task in less time, and as an added bonus you won’t have to deal with irritated staff members who’ve been wrestling with a sprocket all afternoon.

The cost of an install can be calculated using the following equation:

Total Install Cost: (Time x Hourly rate)2 + Cost of Sprocket

Multiply the time spent by the hourly rate of your maintenance operator to find out the total labor cost of the install. We then multiply this number by two: one install and one uninstall for the life of the sprocket. Finally, we add the cost of purchasing the sprocket. The result is the total cost for the installation of that sprocket. We can follow the same process with a split sprocket to compare the cost against a similar sprocket with a solid hub.

Solid Hub Sprocket

| 4 hours x $28/h (salary) | 112 |

| x2 (install and uninstall) | 224 |

| + Cost of Solid-Hub Sprocket | 110 |

| Total | 334 |

Split Hub Sprocket

| 0.25 hours x $28/h (salary) | 7 |

| x2 (install and uninstall) | 14 |

| + Cost of Split-Hub Sprocket | 170 |

| Total | 184 |

Total Savings: $150

There will be additional savings beyond this number that won’t appear on your installation invoice, namely the savings resulting from reduced operation downtime. Any time spent installing a new sprocket is time you can’t generate income using that machine.

There is also a size threshold where it becomes more economical to ship sprockets in pieces rather than as one big sprocket. We’ve had sprockets come through our shop taller than any of our manufacturing crew, and that makes for one big, expensive parcel!

While sprockets split in two pieces are the most common, it is also possible to split sprockets into three or four pieces. Generally, this option is chosen in situations where the sprocket would be unmanageable even when split in half.

Split segmental sprockets require complex mounting hardware in order to match the working strength of a solid sprocket. Like standard split sprockets, split segmental sprockets should be welded on the seams for optimal performance.

The main downside to split sprockets is the increased cost. There‘s a threshold where the labor cost involved with installing a solid sprocket exceeds the sticker price of a comparable split-hub sprocket, but that’s not always the case.

If your machinery setup provides access to the sprockets needing replacement without having to disassemble the machine, or if your setup utilizes extremely small sprockets, solid sprockets might be significantly cheaper for your application.

For example, if a small solid sprocket is $50, and the split-hub equivalent is $120 (to account for the extra machining time and components), it might be cheaper just to go with the solid sprocket, even when you factor in the additional labor time.

You can find more information on split sprockets – including our full product line – in our catalog, and if you would like a cost comparison for solid and split options in a particular size get in touch with us here!

There are two main types of industrial chain: round link chain and engineered chain. While engineered chain for power transmission […]

Read MoreContents: What Happens When Steel Is Heated? What’s the Difference Between Hardened and Mild Steel? Flame Hardening Advantages Disadvatages Induction […]

Read MoreOne question we get all the time is “What’s the difference between surface hardened and through hardened steel?”. While both […]

Read More