Lowering your bottom line. Raising your quality standards.

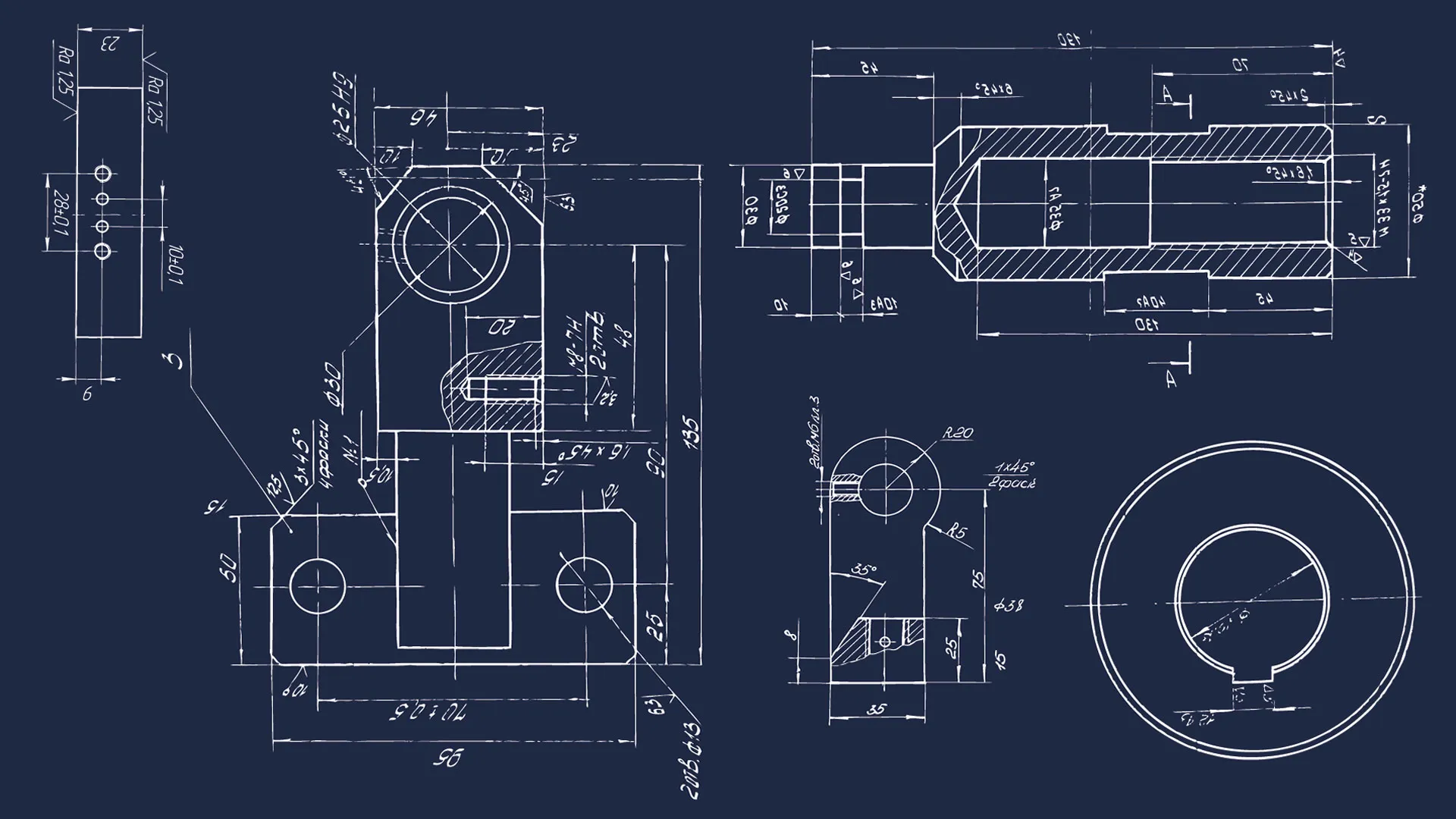

All our in-house CNC machining capabilities boast accuracy up to 0.001” – allowing you to achieve significant cost savings without sacrificing quality.

Delivering best-in-class quality at every quantity.

With bed sizes up to 84” x 32” x 30”, 32 tools per machine and our live tool capability with 10-tool turret, our machining services allow for short and long run production projects, mid to high volume production, as well as small or large part production.

Between our multiple metal machining facilities in the Midwest, Wisconsin, Illinois, Canada, and more, we are prepared for any custom project requirement you have.

CAPABILITIES

- Drilling

- Milling

- Tapping

- Turning

- Multi-axis Machining

- Beveling

- Max Diameter of 9 inches

EQUIPMENT

- 1x 15” Clausing Colchester lathe

- 1x Bridgeport Series I, with digital readouts

- 1x Delta 1HP drill press

- 3x Haas VF2 CNC vertical machining centers

- 2x Haas VF3 CNC vertical machining centers

- 1x Haas VF6 CNC vertical machining center

- 1x Haas ST-20Y with Automatic Bar Feeder

- 1x Haas DM1 with Midaco Automatic Pallet Changer

- 1x Haas GR 510

- 3x Procunier tapping heads

Ready to start your project?

Contact us for a tailor-made quote just for your project.

We have lower minimums than our competitors while still achieving high yields and on-time delivery. With metal fabrication facilities in the Midwest, including Illinois and Wisconsin, as well as other parts of North America, over 99.9% of our orders are delivered on time, guaranteeting your project meets your deadline.

Reach out to our team at any time!